Project Background

A Fortune 500 tyre manufacturing company in Shanghai is in the rubber and plastic products industry and its moulding plant needs to assemble tyre semi-finished materials into vehicle tyres. With the increasing demand for orders, in-plant inventory space and labour costs, the problem of storing tyre wire edges is becoming increasingly acute. How to store more tyres in a limited warehouse and effectively manage the production of these tyre semi-finished products has become an urgent challenge for the project. The conventional AGV/AMR automation solution was limited in the limited space, as it needed to reserve the aisle for AGV/AMR passage, resulting in a limited number of cargo spaces; and in the confined space, the speed of AGV/AMR could not be increased, resulting in low storage efficiency. Through repeated consideration and discussion of the project scenario, Shanghai Denensity Technology Co., Ltd. adopted a four-way shuttle with a more flexible space layout to provide a set of automated dense stereo warehouse storage solutions for meeting the comprehensive management requirements of the factory's lineside storage.

Project challenges

(I) Limited space in the plant

Due to the long duration of the plant for this project, the early landing of the tyre production line in the workshop, the small amount of tyre storage area available in the plant, as well as the need to reserve space for tyre transfer routes, the cargo space design was difficult.

(II) Noise needs to be less than 80 dBA

For humane production requirements, all equipment needs to operate with a noise level of less than 80dB, which requires the solution to be implemented on the ground with a noise level of less than 80dB.

(III) The equipment needs to operate stably over a long period of time

This is a mandatory requirement of 90 days of continuous operation in normal production with a failure rate of less than 5%.

Solutions

(I) Fully modular cargo space to meet project requirements

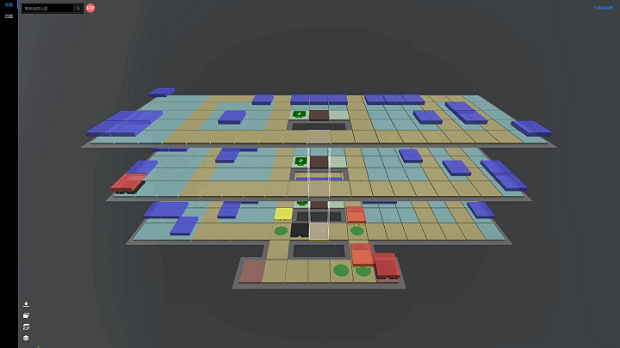

Density has designed a three-storey warehouse with a total of 42 spaces for the customer through a site visit to the project, combined with the actual use and needs of the project. The modular design of the warehouse allows for the addition and removal of spaces at any time, avoiding any shortage of spaces.

(II) Proven project solutions

Thanks to the quality of the product, the noise generated by the whole set of equipment is below 80dB, which meets the actual requirements of the project.

(III) Modular design of the whole vehicle, ultra-reliable product quality

Density always upholds a product belief - not to practice with customers. All products have passed the MTBF test of not less than 1000h, and the maintenance-free time of the transmission parts is not less than 2000h, which is much higher than the performance of the industry products. And the modular design of the whole vehicle, can easily complete the product performance upgrade, parts maintenance, fully realize the customer's long-term stable operation requirements.

(IV)Flexible Business Matching System - RCS

In addition to the hardware, Density also provided the customer with a low-code business interface system, RCS, which enabled a seamless interface between the customer's original business logic and the production management of the automated equipment, as well as the ability to monitor the operational status of the equipment through the RCS 3D form, providing a better Integrated management system.

Customer Testimonials

Density's high-density intelligent storage solution is the perfect solution to the actual project requirements, the existing Phase 1 project is running stably, the storage capacity has increased by 2.5 times and the efficiency has increased by 100%. The client has indicated that the second, third and fourth phases will also use Density's high-density intelligent storage solution, and is looking forward to cooperating on more projects in the future.

Since its establishment, Density has served a number of industries, such as a Fortune 500 tyre wire-side warehouse for auto parts; a finished fastener warehouse in Chongqing for the retail industry; and scenarios such as raw material warehouses, finished goods warehouses, the garment industry, the retail industry, the e-commerce industry, the home industry, the 3C manufacturing industry, and the pharmaceutical industry. Please contact us for more information.